Gash Grinding – the challenge

- Gashing requires higher profile consistency (of the grinding wheel) in comparison to fluting, due to the high edge quality required of carbide tools. However, there may still be substantial material removal in the gashing of end cutters. Hence, the demand for large removal capacity is high in this case as well.

- In the gashing operation, contact area is relatively large, requiring proper cooling.

- A peripheral speed of 20-30 m/s is recommended.

- Higher speeds make the wheel work harder, thus requiring more cooling.

- Lower speeds make the wheel work softer, which means rapid wear, but less cooling required.

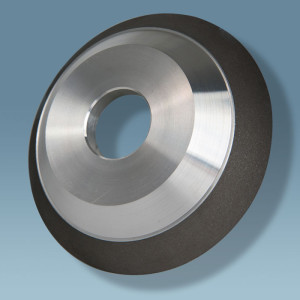

- The Toolgal RM6/5 Gash Grinding wheels are very effective in the gashing operation, with very large stock removal capacity and high profile consistency.

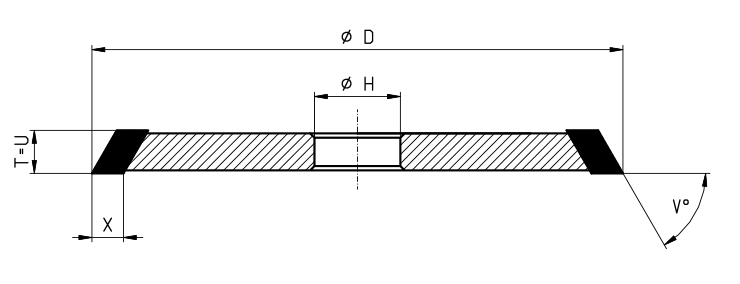

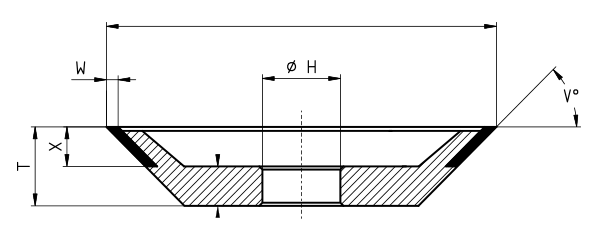

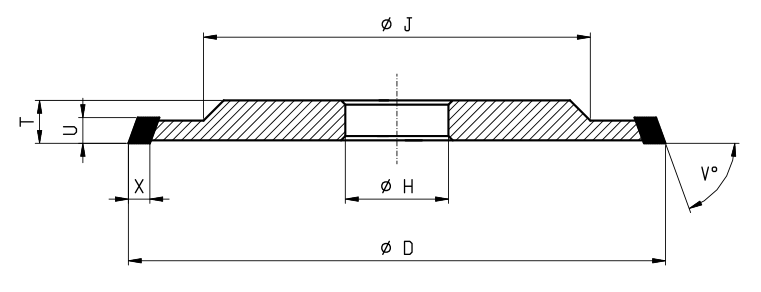

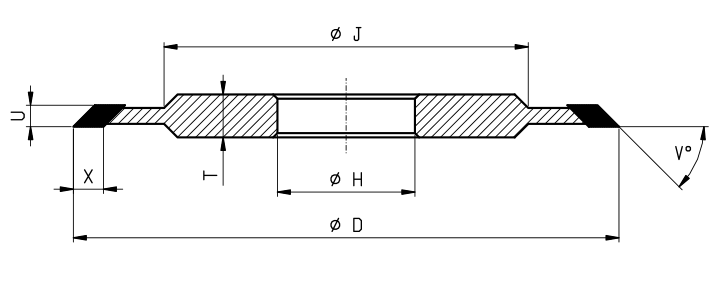

- Suitable Shapes 1V1, 3V1, 14V1, 12V9

Request a sample or Information

3V1 14V1

| 3V1 / 14V1 | Bonds Available | ||||||

| D | U | X=6mm | X=10mm | Diamond | CBN | ||

| 50 | 2,4,5 | 6 | RM5 | RM9 | |||

| 50 | 6,8,10 | 6 | 10 | RM6 | RM5 | RM9 | |

| 75 | 2,3,4,5 | 6 | RM5 | RM9 | |||

| 75 | 6,8,10,12,15 | 6 | 10 | RM6 | RM5 | RM9 | |

| 100 | 2,3,4,5 | 6 | RM5 | RM9 | |||

| 100 | 6,8,10,12,15 | 6 | 10 | RM6 | RM5 | RM9 | |

| 125 | 2,3,4,5 | 6 | RM5 | RM9 | |||

| 125 | 6,8,10,12,15 | 6 | 10 | RM6 | RM5 | RM9 | |

| 150 | 2,3,4,5 | 6 | 10 | RM6 | RM5 | RM9 | |

| 150 | 6,8,10,12,15 | 6 | 10 | RM6 | RM5 | RM9 | |

Downloads: